FEATURES

- Traceable to SI 1

- High Flow Capability of 10 L/min

- Based on NIST Proven “Two-Pressure” Principle

- 3920 ControLog® Embedded Automation Software

- HumiCalc® with Uncertainty Mathematical Engine

- Generate: Frost Point, Dew Point, PPM, %RH

- Calculated Real-Time Uncertainty

- Calculated Water Capacity to Indicate Water Usage

- 10.1" Multi-point Touch LCD

- Added Keyboard Interface

Get Software

1 Traceable to the International System of Units (SI) through a national metrology institute (NIST) recognized through a CIPM MRA.

SPECIFICATIONS 2

UNCERTAINTY 2,5 & 6

2 Test pressure at 1 atmosphere.

3 Using anhydrous methanol as the temperature heat transfer fluid from –80 to 12 °C.

4 Temperature Control Stability is defined as the standard deviation over a 10-minute period, as measured by the saturation temperature control sensor after being at point for 60 minutes.

5 Uncertainty values represent an expanded uncertainty using a coverage factor, k=2, at an approximate level of confidence of 95%.

6 Uncertainty is based on specifications from the 3920 uncertainty analysis.

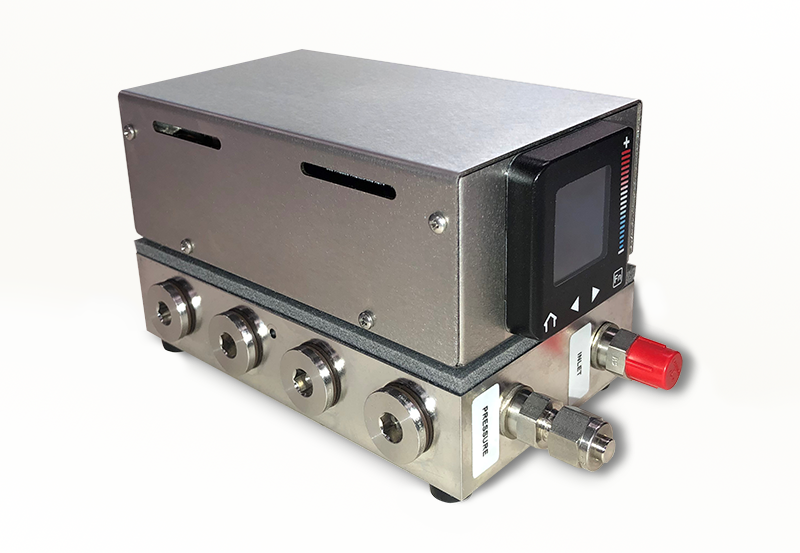

UTILITIES

ENVIRONMENTAL

Note: The specifications listed, and the information contained within this web page are subject to change without notice.

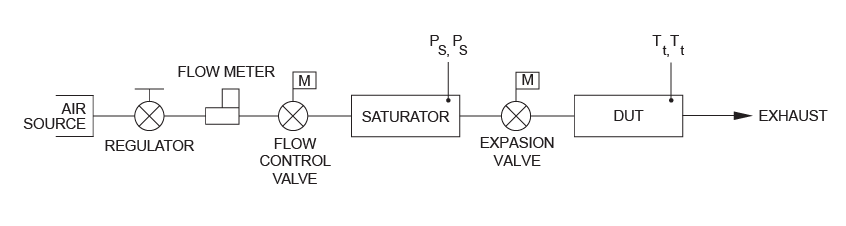

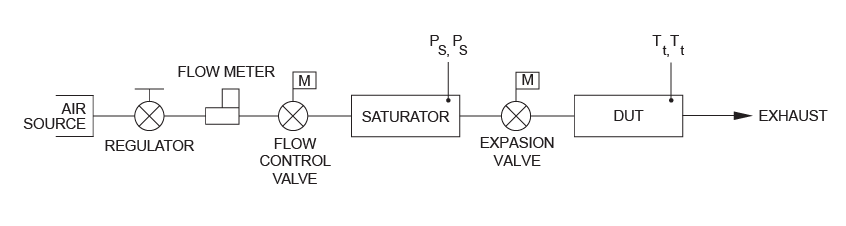

PRINCIPLE OF OPERATION

The “two-pressure” humidity generation process involves saturating nitrogen with water vapor at a known temperature and pressure. The saturated high-pressure gas is then reduced to test pressure and warmed to test temperature. The indication of saturation temperature, saturation pressure, test temperature, and test pressure is used in the determination of all hygrometric parameters. Humidity generation by this system does not depend upon measuring the amount of water vapor, but it is dependent on the measurements of temperature and pressure alone. The precision of the system is determined by the accuracy of the temperature and pressure measurements and on the constancy of them throughout.

Elemental Schematic of the 3920 generator.

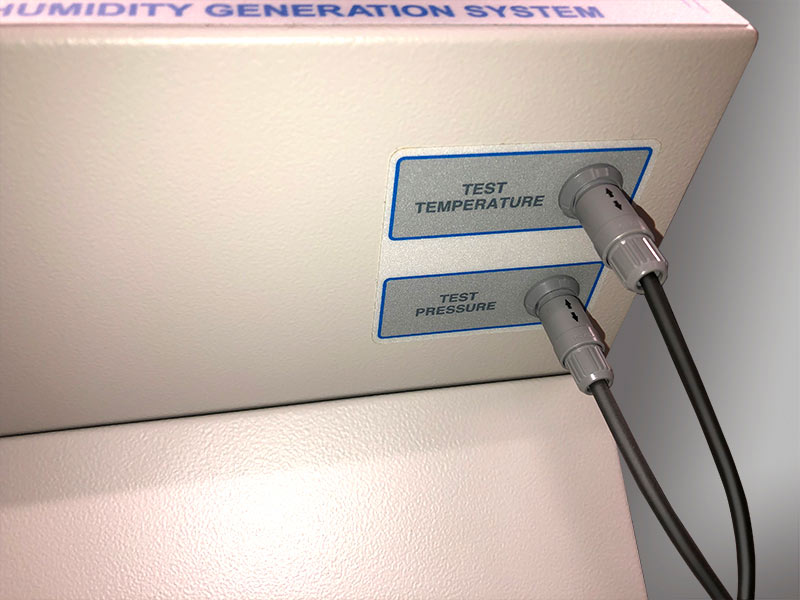

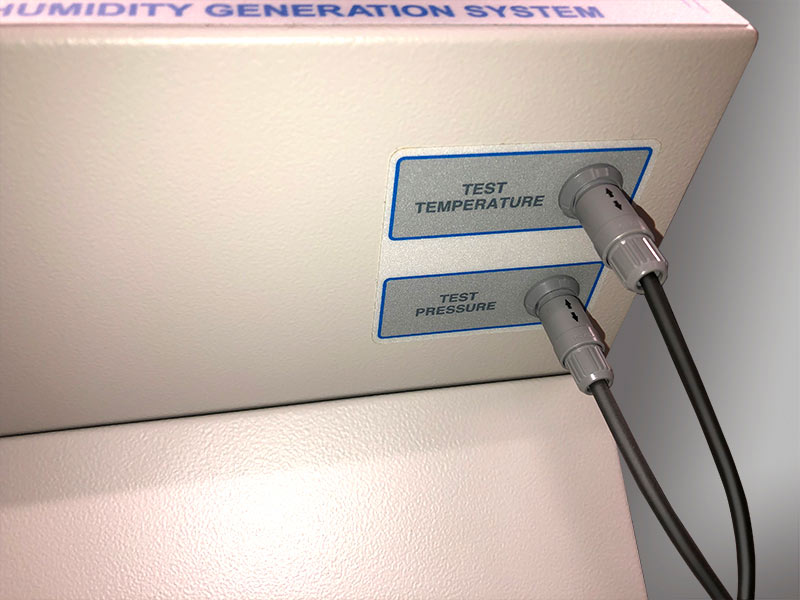

Test Temperature & Test Pressure connectors.

COMPUTER CONTROL

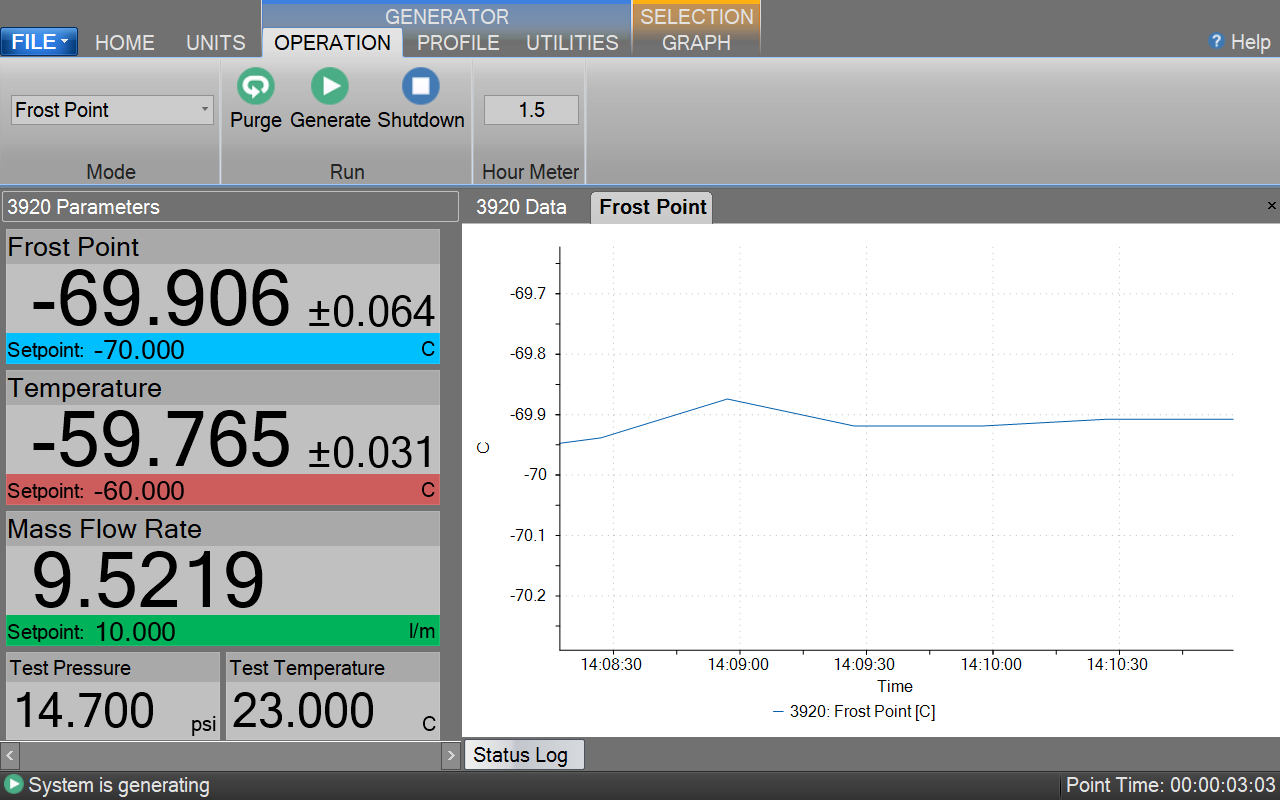

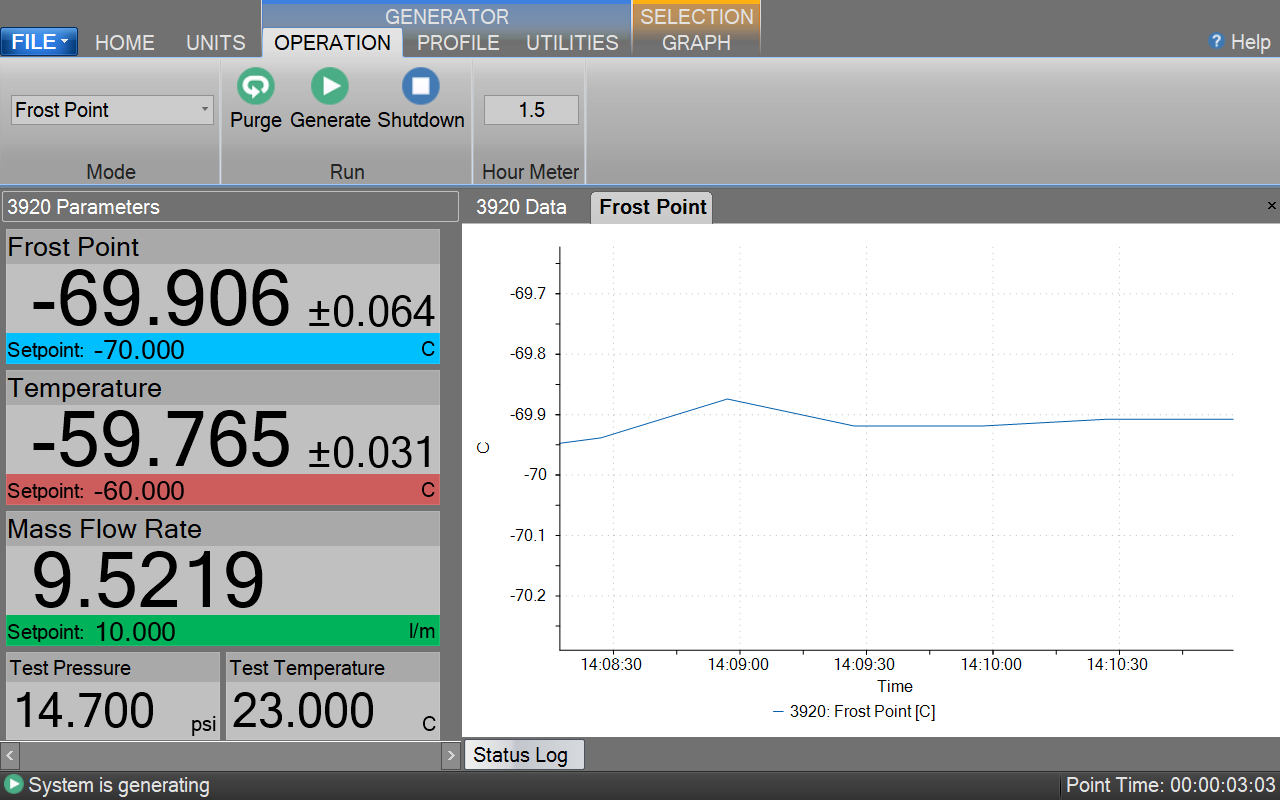

3920 Control Display Screen

Control / Display Screen

The 3920 Low Humidity Generation System encompasses a high-performance stand-alone Control System that performs all functions required for humidity generation and control. The Control System employs 24 bit I/O modules with integrated signal conditioning to acquire analog data, serial interfaces to acquire digital data from the transducers, and digital stepper motors to control the operation of generating humidity. The Control System utilizes an embedded operating system in conjunction with specialty software to control and interface with the human to machine interface (HMI) computer running ControLog.

ControLog is an embedded software application that fully automates the operation of the 3920 Low Humidity Generation System and allows various device connections through a number of different interfaces. ControLog uses Thunder Scientific’s HumiCalc with Uncertainty as its mathematical engine for computing all humidity values and real-time uncertainties. Data from the generator and attached devices is automatically retrieved and stored for viewing in either numerical or graphical format in real time or post process. Data can be transferred off the system via a USB drive for further viewing, post processing and printing using an external Windows PC. The ControLog software also provides the primary interface to the operator via the multi-point touch LCD.

An external Windows PC can also be connected via an RS-232 connection to run a desktop version of ControLog. The desktop version has the same functionality as the embedded version but runs on a stand-alone Windows PC (not included). This allows the user to operate the software with larger displays or on specific computer networks to aid in file saving and transfer. During desktop operation the embedded version locks out user setpoint changes but still allows data viewing and graphing.

Temperature Control: Temperature setpoint control is attained by controlling the temperature of a circulating fluid medium that jackets the saturator of the generator. The saturation temperature is governed by the temperature of this medium, which is digitally controlled by the computer at any value between –80 °C and 12 °C through the use of PID (proportional-integral-derivative) algorithms.

Pressure and Flow Control: Pressure control and mass flow rate control are accomplished through computer actuation of electromechanical valve assemblies. Saturation pressure and mass flow are measured continuously and controlled using PID algorithms similar to those employed in temperature control.

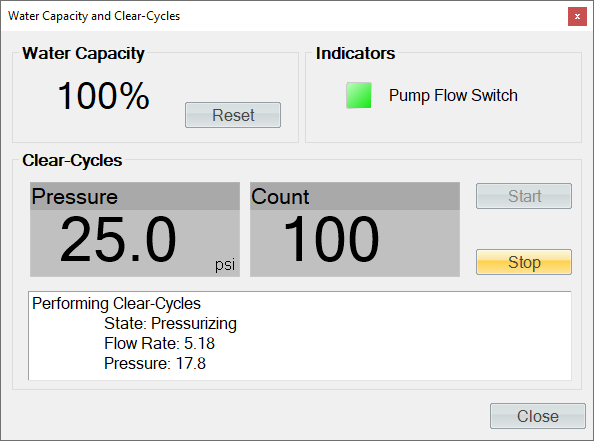

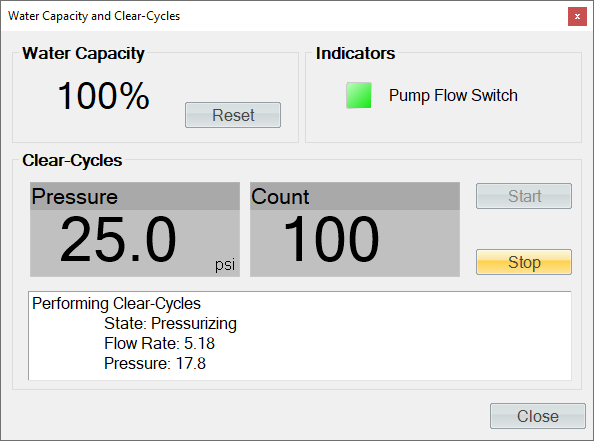

Water Capacity and Clear-Cycles Screen

Water Capacity and Clear-Cycles Screen

Calibration: Proper calibration of the temperature and pressure transducers ultimately determines the accuracy of the generator. This system employs an integral programmatic calibration scheme allowing the transducers to be calibrated while they are electrically connected to the humidity generator.

APPLICATIONS

Chilled Mirror Hygrometers: Connecting the generator output to a chilled mirror hygrometer allows the user to verify the mirror temperature measurement accuracy; perform operational checks on the hygrometer components; determine whether the hygrometer is controlling the mirror in the liquid phase or ice phase when operating below 0 °C; determine if the hygrometer is correctly calculating other humidity parameters; determine hygrometer repeatability, stability, and drift characteristics.

Humidity Sensors and Electrolytic Hygrometers: Connect the generator output to a electrolytic hygrometer, sampling system, special fixtures, or sensors allows the user to calibrate and/or characterize humidity sensitivity; perform operational checks such as the sensing systems capability to correctly calculate and display other humidity parameters; determine repeatability, stability, hysteresis, and drift characteristics of various humidity sensing systems.

Environmental Testing: The 3920 can serve as a test bed for evaluation and R&D of humidity sensors, humidity sensing systems, and humidity sensitive products, e.g., polymers, composites, film, magnetic medium, pharmaceuticals, soil hydrology, consumables, electronics, optics, etc.

REFERENCE DOCUMENTS

Model 3920 Automated Low Humidity Generation System Documents

Series 3920 operation and maintenance manual for the two-pressure two-temperature Automated low humidity generator.

Model 3920 Uncertainty Analysis

This document describes a complete uncertainty analysis of the Model 3920 in accordance with NIST Technical Note 1297. Each error source is identified, quantified, and combined to form an expanded uncertainty using a coverage factor, k=2, at an approximate level of confidence of 95%.