FEATURES

- 0.5 %RH Uncertainty 1

- Traceable to SI 3

- Based on NIST Proven Two-Pressure Principle

- Generate: RH, DP, FP, PPM, Multipoint Profiles

- Computerized Internal Transducer Calibration

- Computes System Uncertainties in Real Time

- Automatically Applies Enhancement Factors

- No Refrigerants - Thermoelectric Cooling/Heating

- Only 4 square feet of floor space (20" x 30")

- Touch-screen control

- USB and Ethernet Interface

- Chamber Circulation Fan

- Oil-Less Compressed Air System w/Membrane Dryer (Option)

- 1200 Utility Cart with Power Strip (Option)

1 Represents an expanded uncertainty using a coverage factor, k=2, at an approximate level of confidence of 95%.

3 Traceable to the International System of Units (SI) through a national metrology institute (NIST) recognized through a CIPM MRA.

SPECIFICATIONS

1 Represents an expanded uncertainty using a coverage factor, k=2, at an approximate level of confidence of 95%.

2 When operated at temperatures within 10 °C of room ambient temperature.

Other custom options are available.

UTILITIES

ENVIRONMENTAL

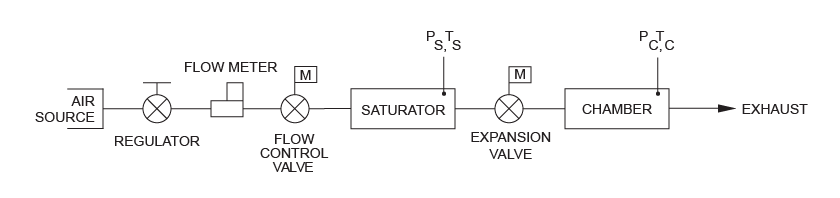

PRINCIPLE OF OPERATION

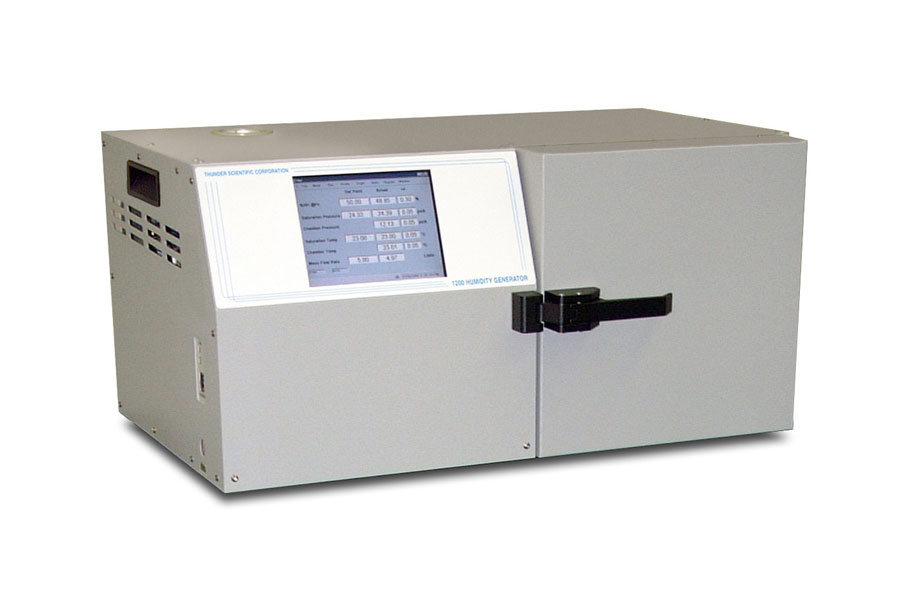

1200 Test Chamber

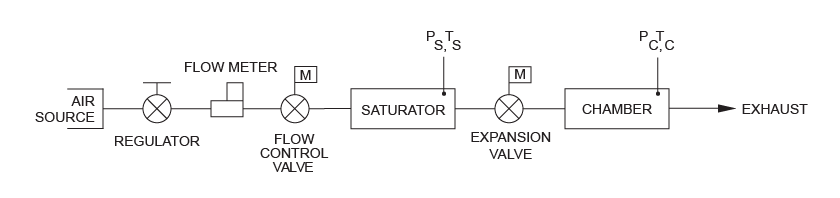

The "two-pressure" humidity generation process involves saturating air or nitrogen with water vapor at a known temperature and pressure. The saturated high-pressure air flows from the saturator, through a pressure reducing valve, where the air is isothermally reduced to test pressure at test temperature. Humidity generation by the 1200 does not depend upon measuring the amount of water vapor in the air, but rather is dependent on the measurements of temperature and pressure alone. System precision is determined by temperature and pressure measurement accuracy, and on the constancy of the measurements throughout. When setpoint equilibration has been reached the indications of saturation temperature, saturation pressure, test temperature, and test pressure, are used in the determination of all hygrometric parameters.

Elemental Schematic of the 1200 generator.

COMPUTER CONTROL

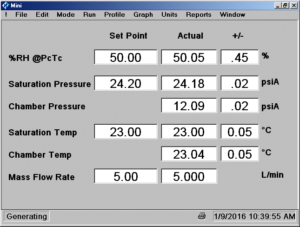

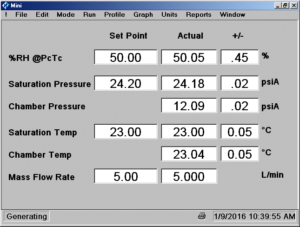

Control / Display Screen

The Computer/Control System performs all control functions required for humidity generation, as well as displaying, printing, and storing system parameters in real time. The computer/controller is made up of several main components, each with individual yet cooperative functions. The Computer/Control System utilizes a Windows based computer system that is used to read transducers and temperature sensors; supply digital outputs for control of temperatures, pressures, and mass flow; and control relay outputs for control of system power, heaters, heat pump and circulation pump.

The Computer/Control System performs all control functions required for humidity generation, as well as displaying, printing, and storing system parameters in real time. The computer/controller is made up of several main components, each with individual yet cooperative functions. The Computer/Control System utilizes a Windows based computer system that is used to read transducers and temperature sensors; supply digital outputs for control of temperatures, pressures, and mass flow; and control relay outputs for control of system power, heaters, heat pump and circulation pump.

Temperature Control: Ultra stable temperatures are attained through solid-state thermoelectric cooling and heating of a circulating fluid that jackets the test chamber and associated humidity generation components. Chamber and saturation temperatures are governed by this medium which is computer controlled at any value between 10 °C and 60 °C using PID (proportional-integral-derivative) algorithms.

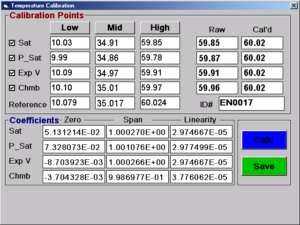

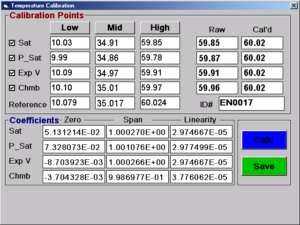

Calibration Display Screen

Calibration: Proper calibration of the temperature sensors and pressure transducer ultimately determines the accuracy of the generator. The system employs an integral programmatic calibration scheme allowing the sensors and transducers to be calibrated while they are electrically connected to the humidity generator. Coefficients for each transducer are calculated by the computer and stored to memory.

Calibration: Proper calibration of the temperature sensors and pressure transducer ultimately determines the accuracy of the generator. The system employs an integral programmatic calibration scheme allowing the sensors and transducers to be calibrated while they are electrically connected to the humidity generator. Coefficients for each transducer are calculated by the computer and stored to memory.

Pressure And Flow Control: Pressure control and mass flow control are accomplished through computer actuation of electromechanical valve assemblies. Pressure and flow are measured continuously and controlled using PID algorithms similar to those employed in temperature control.

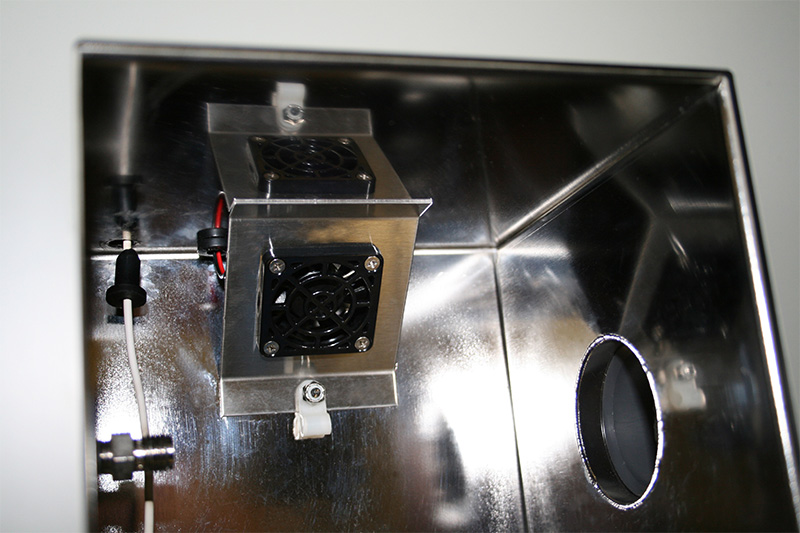

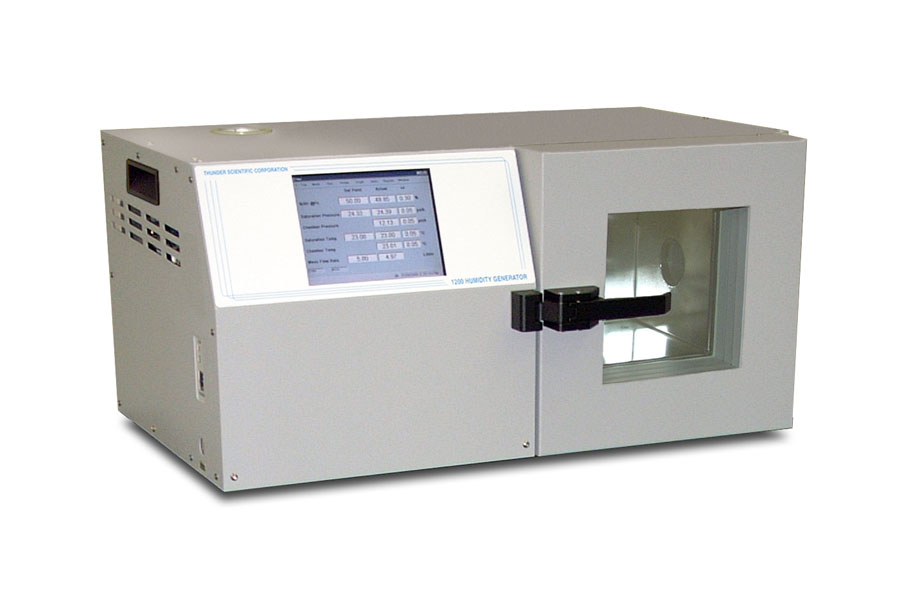

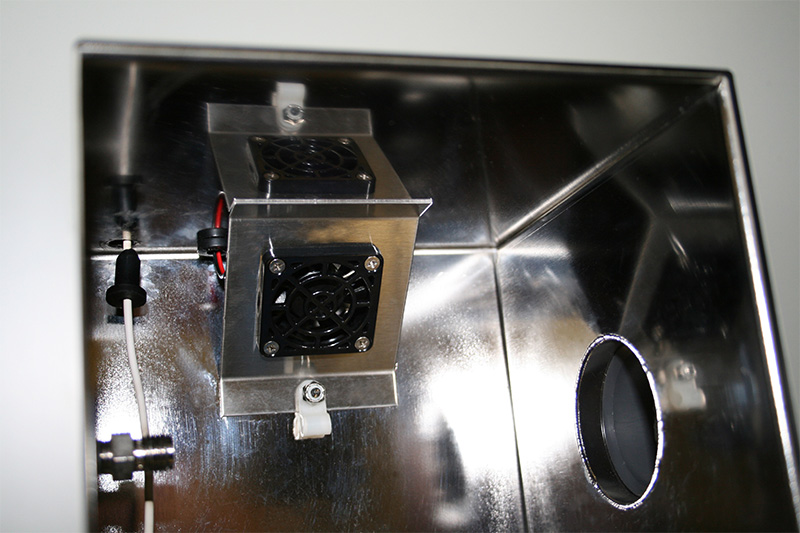

Chamber Fan

Chamber Fan

The model 1200 system comes with an internal chamber circulation fan which provides improved uniformity.

APPLICATIONS

Virtually any humidity and temperature may be generated within the operational limits of the generator. The output or recording of the device under test may then be compared with the generator’s data for analysis.

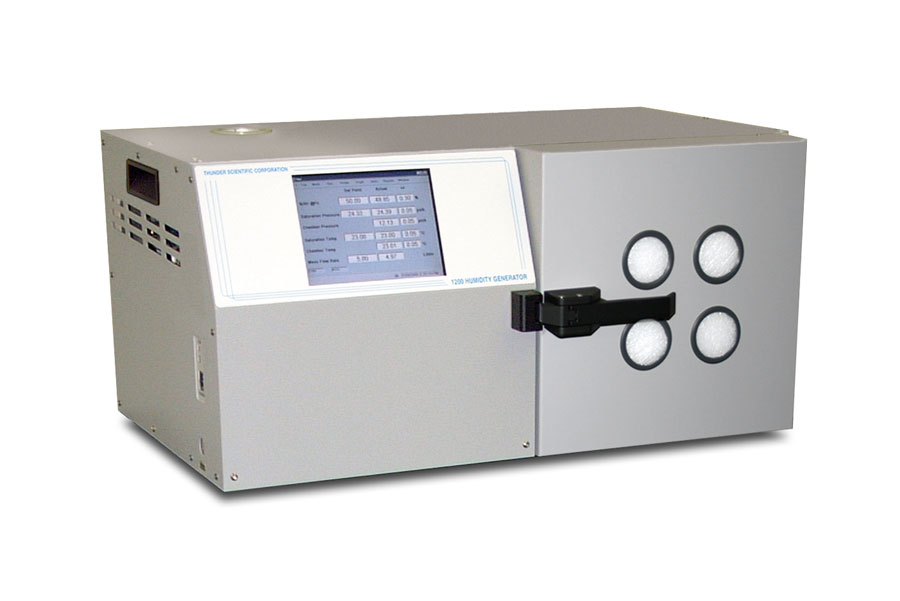

Chilled Mirror Hygrometers: Install the actual chilled mirror head into the chamber or insert a sample tube through the test port and draw a sample through the chilled mirror head and you can: verify mirror temperature measurement accuracy (calibration) when the hygrometer is in thermal equilibrium with its environment; perform operational checks of the heat-pump and optical components before and after mirror cleaning and balancing; determine whether the hygrometer is controlling the mirror deposit in the liquid phase or ice phase when operating at dew and frost points below 0 °C; determine if the hygrometer is correctly calculating other humidity parameters; determine the hygrometer’s repeatability, stability, and drift characteristics.

Humidity Sensors and Data Loggers: Insert your humidity probes through the chamber access port or install the data logger into the chamber and you can: determine humidity calibration accuracy and/or characterize humidity sensitivity by subjecting the humidity sensor to a variety of humidity levels; perform operational checks such as the sensing systems capability to correctly calculate and display other humidity parameters; determine the repeatability, stability, hysteresis, and drift characteristics of various humidity sensing systems.

Environmental Testing: The 1200 can serve as a test bed for evaluation and R&D of humidity sensors, humidity sensing systems, and humidity sensitive products, e.g., polymers, composites, film, magnetic medium, pharmaceuticals, soil hydrology, consumables, electronics, optics, etc.

REFERENCE DOCUMENTS

Model 1200 Humidity Generation System Documents

Series 1200 operation and maintenance manual for the mini two-pressure humidity generator.

Model 1200 Uncertainty Analysis

This document describes a complete uncertainty analysis of the Model 1200 in accordance with NIST Technical Note 1297. Each error source is identified, quantified, and combined to form an expanded uncertainty using a coverage factor, k=2, at an approximate level of confidence of 95%.